- Home

- Products

- Heat Exchanger Processing Equipment

- Return Bend Ring Loader

Return Bend Ring Loader

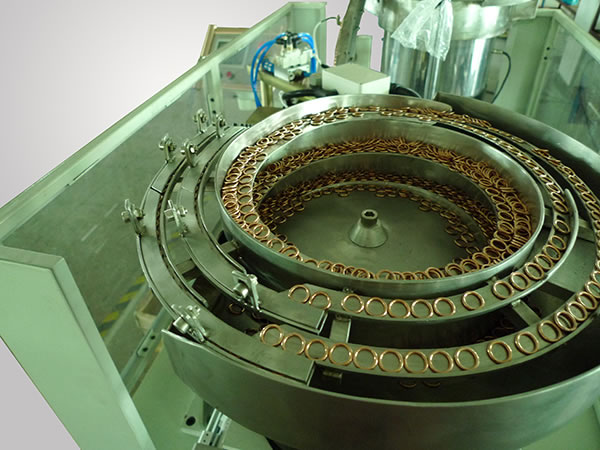

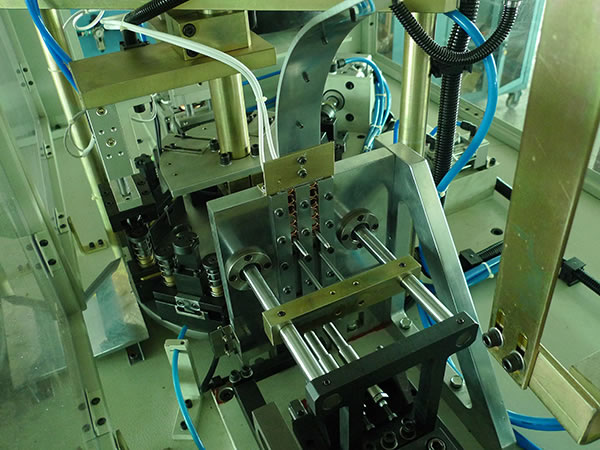

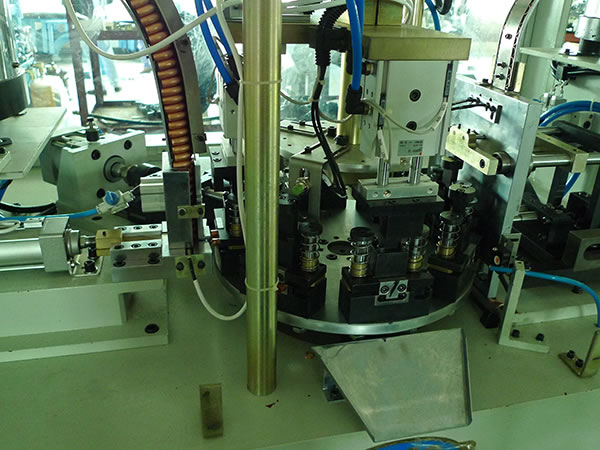

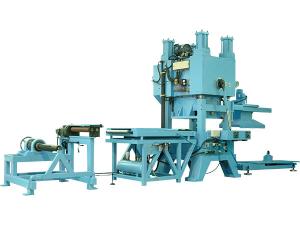

Machine drawing of the return bend ring loader

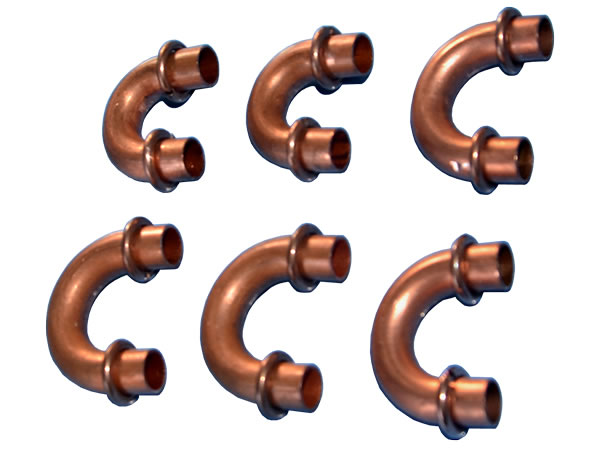

Machine drawing of the return bend ring loader The return bend ring loader is intended to load welding rings onto the return bend automatically. It is used in the production of AC condensers, evaporators, water heaters, etc.

Features:

1. High degree of automation.

2. Convenient operation, exquisite appearance.

3. Scale board on servo motor, accurate location.

4. PLC & touch screen integrated control.

5. Device for smoothing the pipe end.

| Main technical parameters | ||

| 1 | Machining pipe diameter | Φ7, Φ7.94 , Φ9.52 |

| 2 | Efficiency(machining number of per min) | 50-60 |

| 3 | Central distance precision after ring loaded | ±0.1 mm |

| 4 | Depth of ring loaded | 6.0±0.6mm |

| 5 | Distortion rate of pipe end | <3% |

| 6 | Power supply | 3 phase AC 380V±10 % 50Hz |

| 7 | Total power | ≤7.5KW |

| 8 | Pressure of compressed air | 0.4-0.6Mpa |

| 9 | Driving mode of turntable | AC servo motor with precise planet deceleration device |

| 10 | Material loading mode | return bend and welding ring tray material loading |